URL: https://www.desy.de/news/news_search/index_eng.html

Breadcrumb Navigation

DESY News: From basic research to application: Broadly applicable gas pressure sensor filed for patent

News

News from the DESY research centre

From basic research to application: Broadly applicable gas pressure sensor filed for patent

Ever since they were measured for the first time in 2015, gravitational waves, which are produced when black holes and neutron stars collide, for example, have been one of the hottest topics in basic research. At the moment, nobody can say how the findings from this science will affect our everyday lives. However, an invention by DESY researcher Christoph Reinhardt from the ALPS research group and Hossein Masalehdan, a doctoral student at the Institute of Quantum Physics at Universität Hamburg, proves that this science is already giving rise to developments that could find broad application in everyday life: they invented a pressure sensor that can be used over extremely large pressure and temperature ranges and, as a variant, can even identify which gas is flowing around it. They have just been honoured with the DESY Innovation Award for this invention, for which they have also applied for a patent. And together with their working groups they want to develop it further towards market maturity. The DESY Generator Programme, an internal DESY start-up funding programme for transfer projects, is now supporting this development work.

“It was actually about concepts for cooling gravitational wave detectors,” says Reinhardt, explaining the start of their development. In order to increase their sensitivity, such experiments could be cooled down to -260°C using helium in the future. However, there are practically no commercial pressure sensors for this area of application. Reinhardt was helped by an idea he brought back from his doctoral thesis in Montréal, where he had investigated the oscillation of membranes located in a laser light stored between two mirrors. “You can use a system like this as optical tweezers, this is absolutely basic research,” says Reinhardt. But already here he noticed that the membranes interacted with the surrounding residual gas atoms, even when the pressure was very low. This gave rise to the idea of using them for a pressure sensor.

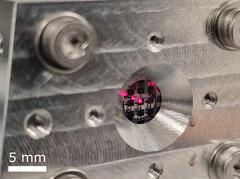

In a test setup, the researchers took a membrane about one square millimetre in size made of silicon nitride, a ceramic material with very low internal friction. They caused it to vibrate resonantly with the help of a piezo crystal. During their measurements at the Institute of Quantum Physics, they discovered that the decay of the oscillation depends very precisely on the pressure of the gas in which the membrane is located. This correlation applies to a wide pressure range from normal atmospheric pressure of approx. 1000 hectopascals (hPa) down to one ten-billionth of this pressure (10-7 hPa). “No other sensor has such a wide measuring range,” says Reinhardt. And the sensor is still very uncomplicated: without further calibration, using only the parameters of the membrane, the sensor already has a measurement accuracy of better than 15 per cent. The research group recently presented this and other characteristics of the new sensor in a scientific publication. “For a more precise determination of the sensor´s properties, we still need to procure better commercial pressure measuring devices,” says Reinhardt.

As next steps, the group wants to determine all the properties and possible functionalities of the sensor more precisely, further develop their invention, and bring it into application – funded by the DESY Generator Programme. “We want to produce a compact prototype that is designed for operation under realistic conditions,” says Reinhardt. For example, the light supply for measuring the vibration is to be provided by fibre optics if the sensor is mounted in hard-to-reach or narrow places. Furthermore, purely electrical readouts are to be developed as a complementary approach to the optical method.

However, also basic research should benefit directly from the new invention, and not just in the field of gravitational wave detection. If the sensor is installed in the beam tube of the ALPS II light-through-the-wall experiment, it could enable the helium pressure in the light storage sections to be precisely adjusted. This would allow to specifically adjust the refractive index of the gas there which extends the sensitivity of the experiment to axion particles with other masses.

Reference

Calibration-less gas pressure sensor with a 10-decade measurement range; C. Reinhardt, H. Masalehdan et al., arxive.org; DOI: 10.48550/arXiv.2309.12044